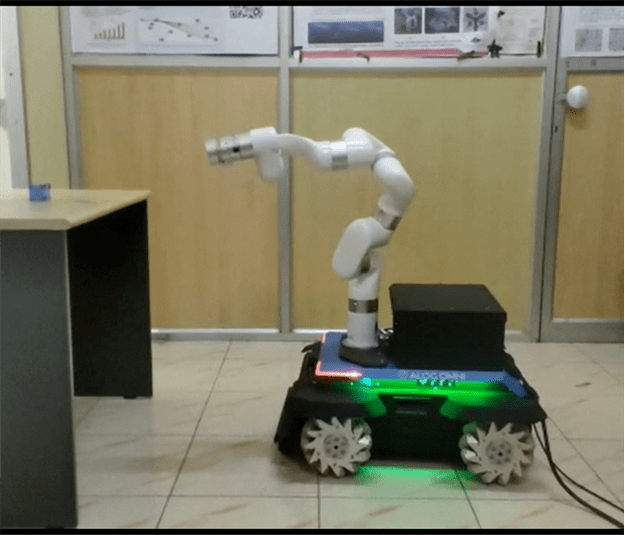

ALOG® ACDC®

Compact multipurpose autonomous mobile robot (AMR) designed to increase productivity of order pickers in fulfilment centers.

ALOG® T-1000

Autonomous mobile robot (AMR) designed to tow trolleys, carry and lift pallet loads in manufacturing facilities.